Digital Manufacturing and Prototyping for Industrial Startups

During the summer of 2019, I had the opportunity to attend a course on Fusion360 in MotionLab Berlin. It started as a Saturday evening entertainment, but many months later, I’m still a Coworker in MotionLab. It is a factory/maker space in Berlin, the dream for an adult kid, full of toys like 3D printers, laser cutters, CNCs, and many other tools.

I would like to summarise my experience, and maybe I would like to discover the fascination myself I had “creating things”.

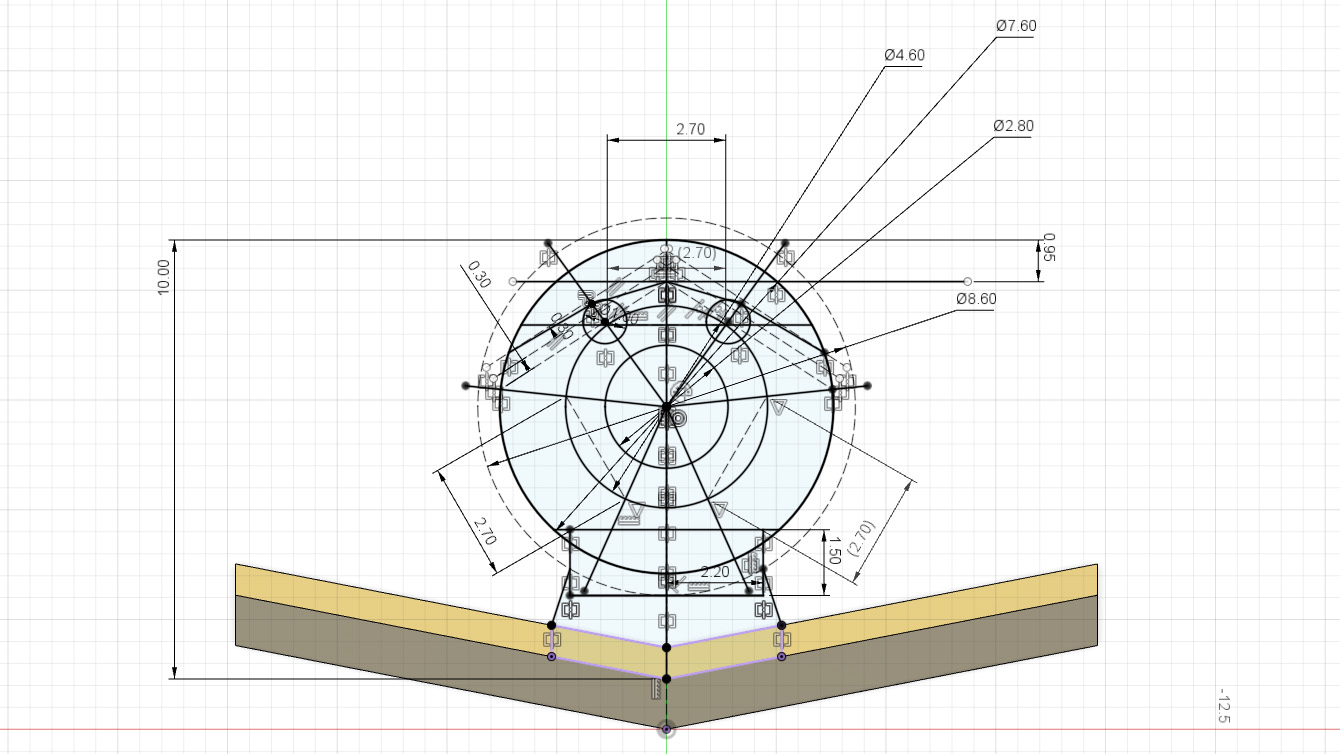

3d and parametric design

3D design was the beginning. For me, it’s incredible that something like Fusion360 is for free. My last contact with CAD was near 20 years ago, and the software licenses were quite expensive. My first fight was with parametric design, a totally new concept and way of thinking for me. A couple of weeks later, well, maybe a couple of months, it was not so complicated.

Even today, I had to start the design with paper and pencil to develop my design strategy before being in front of the computer. Without doing it, I’m very quickly lost. Very frequently, the first model is a mess, and I have to do it again from scratch. It’s required to follow a very clear and disciplined design method and note clear documentation. It would help a lot if you gave a name to the steps you make, and the pieces you create. The significant advantage is that the parametric design changes are like magic, but a small mistake creates a catastrophe.

The main advantages of the parametric design are:

- You have to exploit a very elegant design, and that’s always a positive point.

- The changes are magic

- It’s easy to create a collection of similar products in different sizes and with different features with a very low effort.

The learning curve is hard, but it’s worth it. For me, it was a challenge, nevertheless the fact that I had experience with AutoCAD, unfortunately, 20 years ago. At least I know the names of processes, vocabulary and I’m familiar with the learning process. For a complete beginner, the first steps could be very frustrating.

Ready for manufacturing

After the design, manufacturing starts, which means learning about machines, materials, and manufacturing processes. If not, you will permanently be blocked in the design phase, and in the end, nothing will be produced.

What it’s essential is to understand the different options, which means the more machines to use and the more technics to know as possible. In the world of DIY, 3D printers are the most mentioned ones and seem to be the only alternative, but that’s not true. Learning what’s possible and optimal to create with each one of the machines and tool is critical. My most significant discovery during this time was laser cutting. They are easy, fast and with immense potential.

It’s famous the quote “If you only have a hammer, you only see nails” and here it’s very true. With more alternatives in mind, you can make better decisions in the design and find better solutions for your problem. It is a continuous process, where it’s always possible to learn more, but not with many concepts, and it’s possible to find reasonable solutions.

Here I will show what I learnt. I wrote everything before publishing it, and I’m surprised about the topics I have written the most. The protagonists are how to learn and how to work at the end: the processes. It’s strongly related to my profile, very operations-oriented, but I find it could be helpful. There is much information about the machines, but in order to start in this world, knowing how to organize your work is very needed and frequently forgotten. I hope that my experience will help others.

Version DE